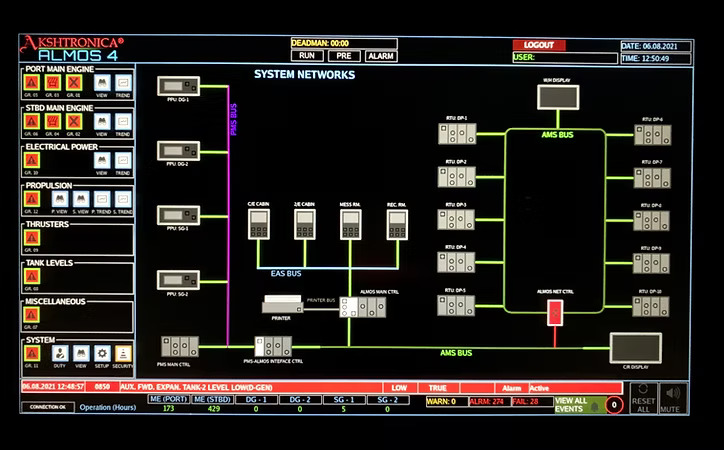

ALMOS 4 Alarm monitoring system works with centralised or distributed signal acquisition units and remote terminal units to acquire, filter, analyse, store and monitor alarms and events. It is standalone, secure an independent from machineries and other engine room equipments.

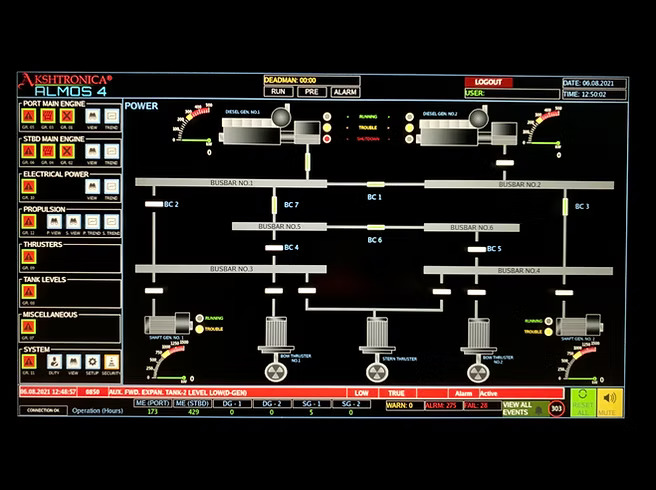

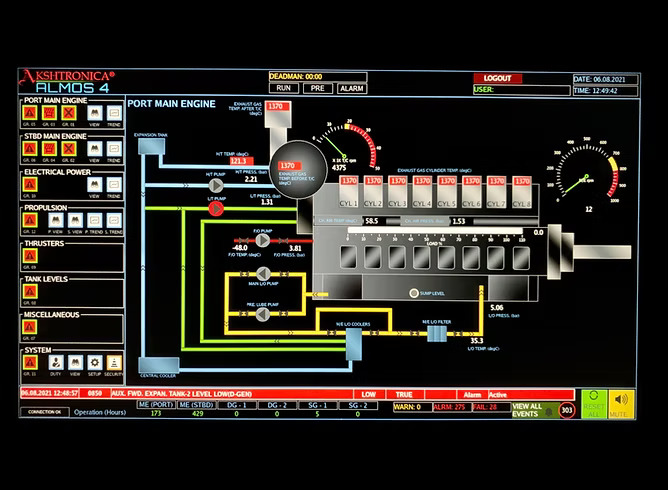

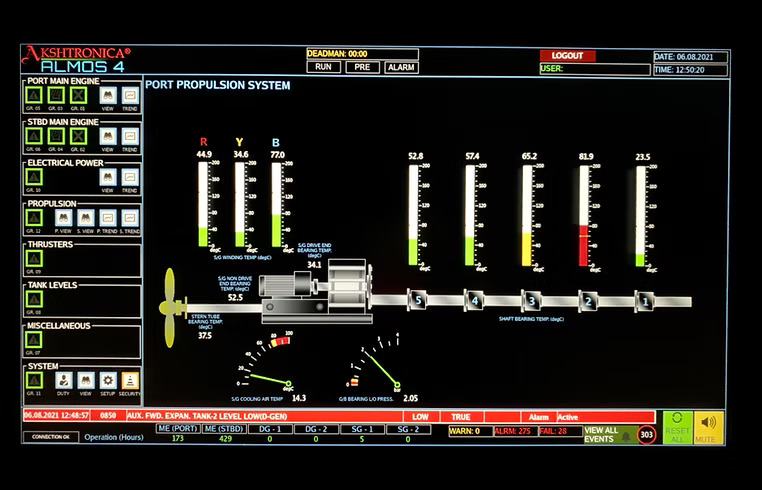

Dynamic mimic diagrams assists the engineers and operators to easily understand the process status and critical parameters. Readings and indications on the mimic are colour coded depending on if they are normal, alarm condition, blocked or inhibited. These diagrams can be designed to illustrate Main engines, Auxiliary engines, Power networks, Shaft and propellors, Boiler and any other process network as per customer requirement.

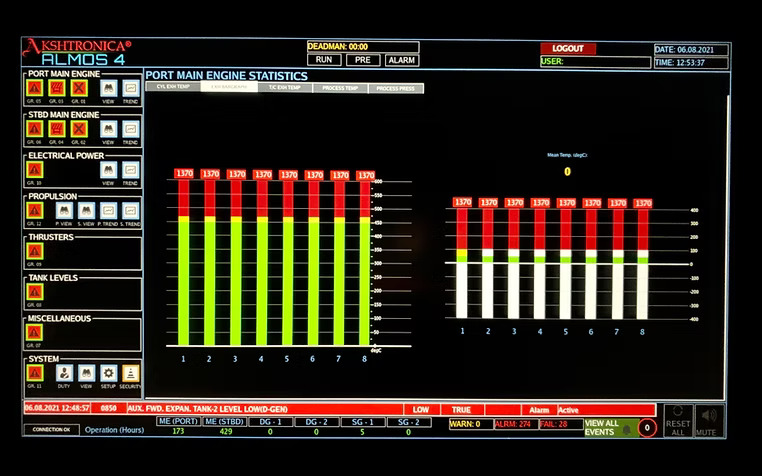

Bar Graphs provided for exhaust gas temperature and mean deviations show the combustion performance of each cylinder making any abnormality very observable in a glance.

Trends for various engine temperature and pressure parameters can be monitored historically to view process system stability.

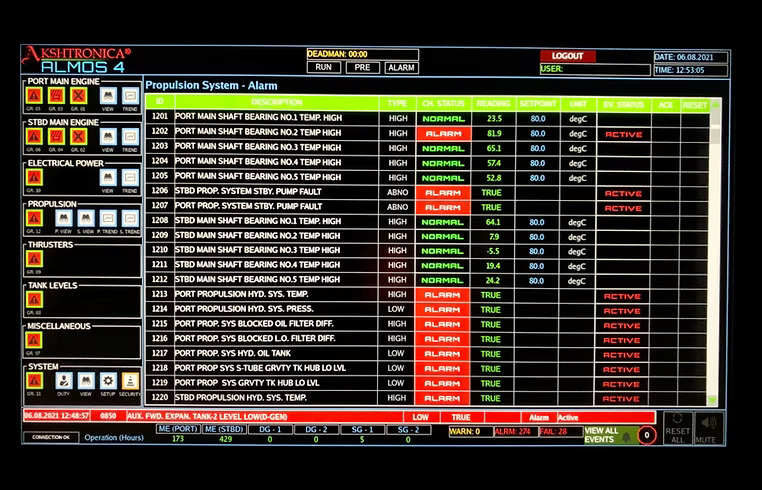

All alarm channels are classified into various machinery wise groups. This list provides full detailed status of all monitoring parameters. It shows the channel number, name, type of channel, current reading, alarm set points, blocking/inhibit status, event acknowledge and reset status. With support for auto-alarm blocking, when any engine, generator or other machinery is shutdown, it will automatically block alarms and events occurring from the respective alarm channels. This will reduce the number of unnecessary notifications to the operators.

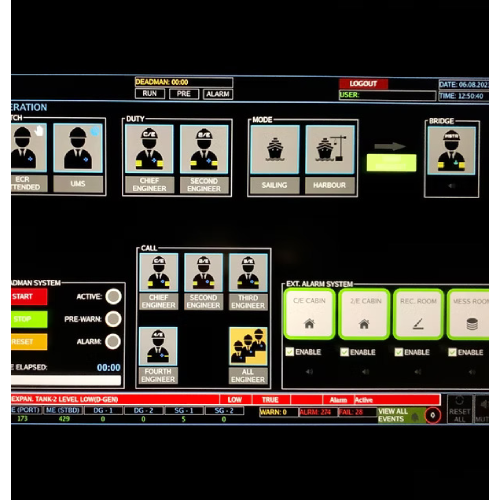

The entire alarm monitoring is secure with multi-level password based security system to ensure that no unauthorised changes can be made to the system.