WAGO, Your Reliable Partner for Marine Technology

Whether freighter or mega yacht, all types of ships face the same tough requirements at sea. Our automation and connection technologies meet the most challenging requirements on the high seas.

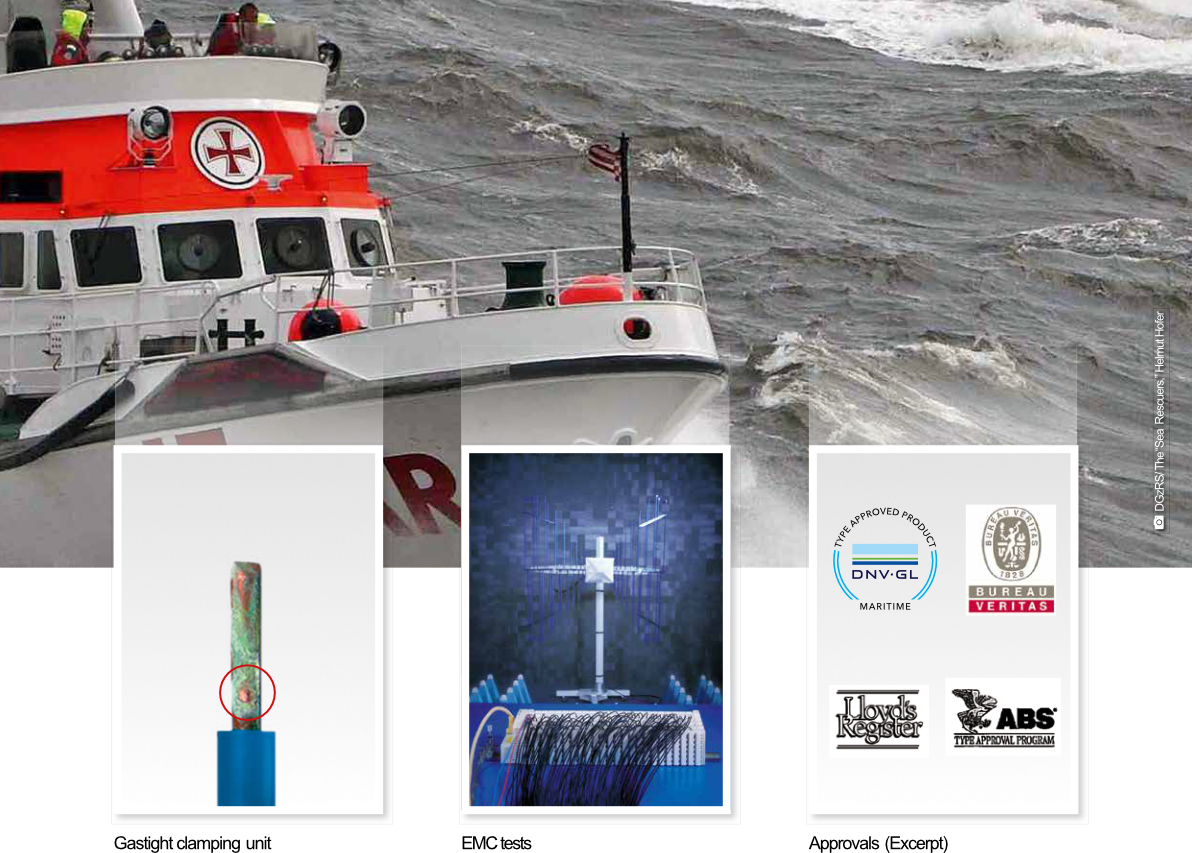

Confirmed by the stamp of classification associations from the IACS Association, WAGO products have proven their strength and durability, ability to withstand extreme temperatures and electromagnetic compatibility (EMC), as well as vibration and shock resistance. These same components also fulfill the requirements for hazardous environments in accordance with IECex and other governing bodies.

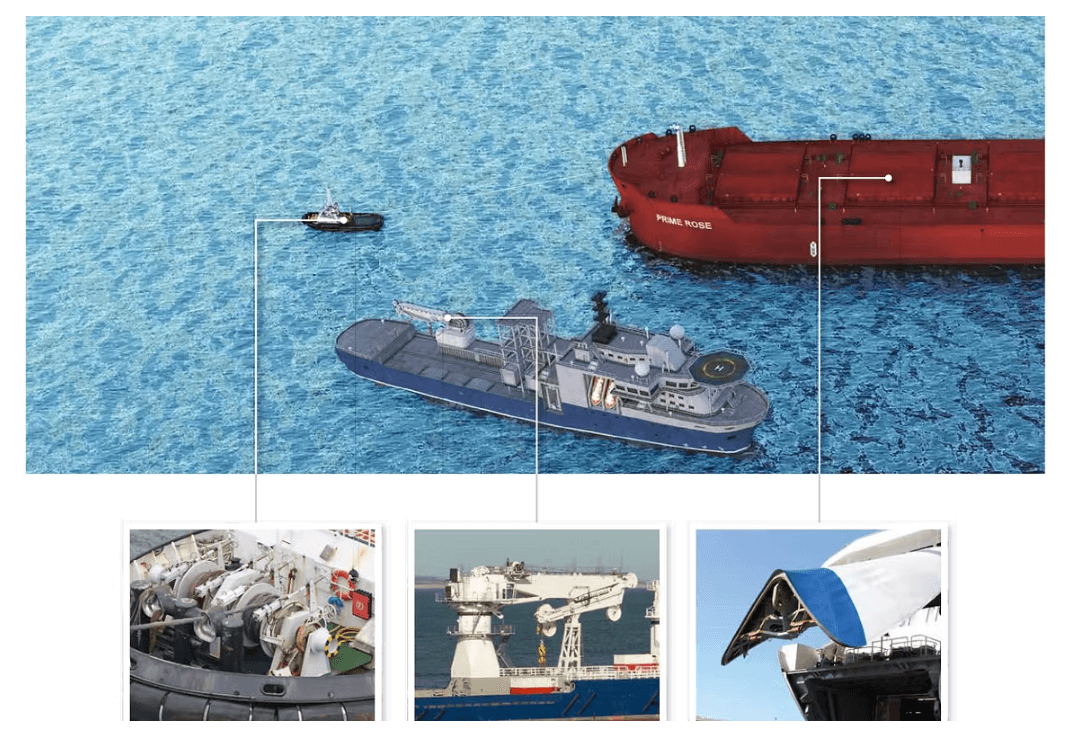

WAGO is at home in all of these applications

From the bridge to the engine room — Automated and reliably connected with WAGO products

Our marine automation and offshore sector products automate nearly every application on board.

Propulsion automation, auxiliary and deck machinery, navigation and communication equipment: Every application has its own special requirements. The answer for continually meeting all of these requirements is WAGO’s relays, optocouplers, signal conditioning modules, power supplies and network switches.

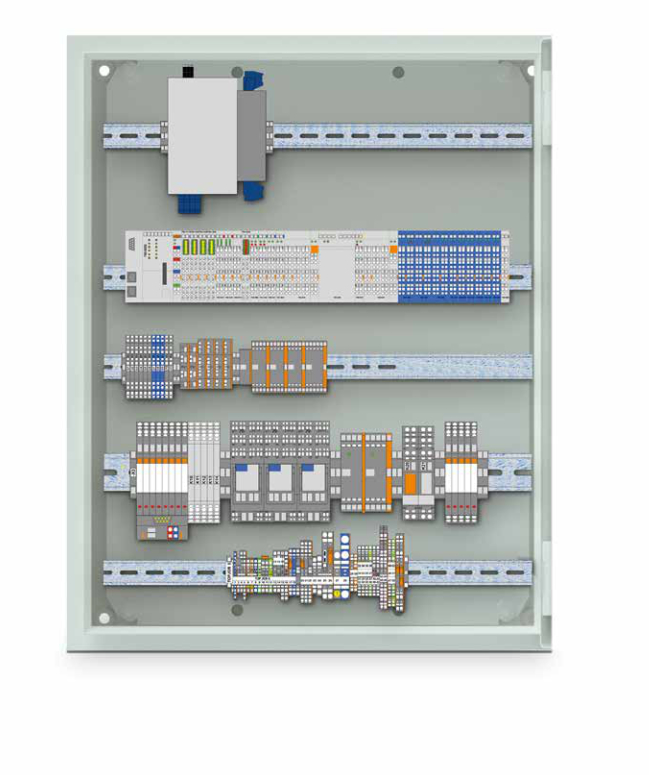

The TOPJOB® S rail-mounted terminal blocks cover wire sizes from 0.08to 185 mm2 —this creates a broad platform for electrical connection technology in marine applications. The same also applies to the more than four hundred modules found in the WAGO-I/O-SYSTEM 750. Special certificates(BSH, near the compass) enable these components to be used everywhere from the bridge to the bilge.

Collecting, conditioning, visualization and notifications/alarms — routine, yet important, tasks that the WAGO-I/O-SYSTEM easily handles.

As an engineering planner, you can implement any conceivable configuration in different network topologies using the modular building blocks of the WAGO-I/O-SYSTEM 750. Whether configuring decentralized intelligence or a central control system with a powerful PLC, a digital or analog signal, valve control or light scenarios for a pleasant ambience, our comprehensive automation portfolio lets you create custom solutions.

The e!COCKPIT engineering platform supports you throughout your products’ life cycle.

Mapping entire topologies and processing multi-controller systems is perfectly compatible with the processing of alarm and monitoring systems with up to 10,000 measuring points. Visualization is based on HTML5 and can be displayed on WAGO displays or on mobile devices.

• Modular, distributed

• Bus-independent, scalable

• Network technology and automation from a single source

Global shipping has made the protection of native species an increasingly important issue. Microorganisms are transported from one biosphere to another in ballast water and can upset the delicate balance of nature. The IMO Convention for the treatment of ballast water has defined limits for this that can only be maintained

using filter systems. A modular, efficient and effective setup with WAGO components will help you minimize the additional costs associated with this.

• General purpose use

• Distributed, modular and approved for use on ships

• Visualization with varying levels of authorization

Maintaining stability in rough seas is vital for freighters. A reliable tank ballast system is a ship’s life insurance against incorrect trim, heel or draught. The anti-heeling system can automate a number of steps for this essential funciton. Rapid loading and unloading can be dramatically simplified with an automated cargo management system.

Ensure safe, uninterrupted running of processes in the event of a fault with a WAGO automation-equipped emergency shutdown system. This solution for protecting people and the environment has long been standard equipment for German- and Italian-built cruise ships.

• Direct valve control from the WAGO-I/O-SYSTEM

• CODESYS controller library

• Set parameters for proportional valves using WAGO-I/O-CHECK

In rough seas or in environmental protection zones, modern tugboats must escort larger ships safely into port. Time is money —in the truest sense of the word — and you have a competitive edge when you can offer your services as frequently as possible and nearly “around the clock.” A high degree of automation for winches and other machines on deck gives you the best possible protection when maneuvering at sea. The same holds true for loading and unloading with cranes and gangway systems at offshore wind farms or oil drilling platforms. A highlight here is the direct control of proportional valves, making expensive valve drivers and proprietary solutions a thing of the past. Parameterization moves into automation at the point where the tool chain is available.

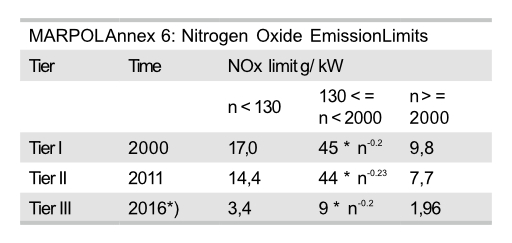

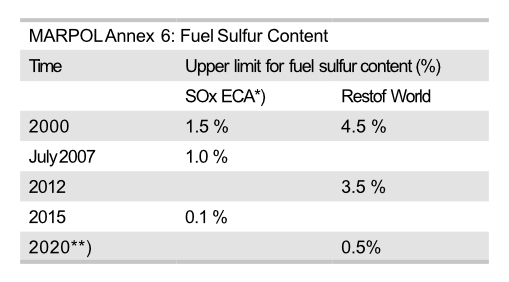

Marine propulsion technology is being put to the test

Buzzwords and terms such as slow steaming, dual fuel, exhaust gas reduction, hybrid propulsion or LNG as a fuel are behind the requirements that are increasing powertrain complexity. In this light, demands for intelligent automation solutions make perfect sense.

The portfolio for the intrinsically safe WAGO-I/O-SYSTEM 750 enables you to automate LNG drives or retrofit scrubber and filter systems for exhaust gas reduction. The 750 XTR Series components are specially designed for extreme hot or cold ambient temperatures and performance under extreme vibration or EMC conditions.

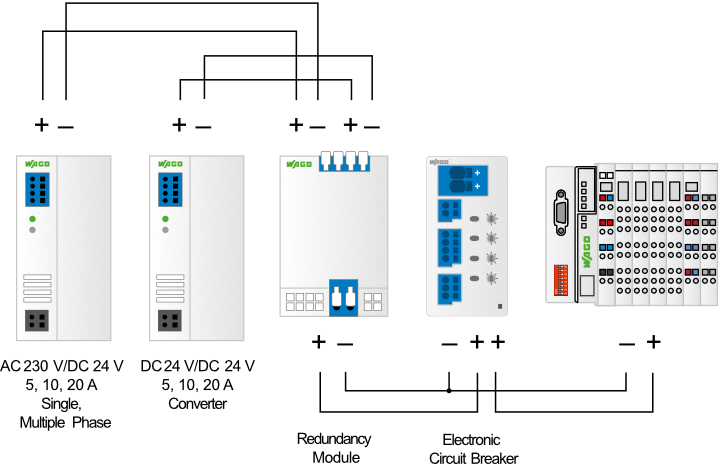

Our power supply modules are designed for more stringent availability and reliability requirements. In the event of a fault, single and multi-phase power supplies and buffer modules ensure the availability of the automation system.

Protection of the secondary circuits is conveniently provided via remote-controlled electronic fuses. Energy measurement terminal blocks for diesel electric drives and a rich portfolio of signal converters and signal amplifiers complete the program.

The WAGO-I/O-SYSTEM 750 XTR is temperature-resistant from -40 °C to +70 °C, vibration-proof up to 5g and features high impulse-voltage withstand according to EN 60870-2-1.

• Intrinsically safe modules for sensors in Zone 2

• Marine-compliant power supply design

• Signal conversion and automation from a single source

WINSTA® and X-COM® :

• Color-coded

• Mechanically coded

• Reduced effort on board

Cruises are becoming more and more popular, prompting a justifiable rise in demands for comfort and safety

The WINSTA® pluggable connection system for electrical distribution is instrumental for the safety and reliability of on board plugged connections. The plugs are pre-assembled under carefully controlled conditions in the workshop. This is a win-win situation: Enhancing wiring quality and minimizing expensive, on board installation times.

Cabin distribution or the dining area — lighting manufacturers are increasingly relying on PCB plugs and sockets from the WINSTA® line.

An ideal complement to the WINSTA® line is the X-COM® plug-in system for rapid plug-and-play control cabinet installations. Two products that perfectly complement one another.

The WAGO-I/O-SYSTEM:

• Modular and distributed

• Access to building automation libraries

• Flexible for signals and bus protocols

As the world market leader and inventor of screwless connection technology, we offer the broadest range of rail-mounted terminal blocks with Spring Pressure Connection Technology, covering a wire range between 0.08–185 mm2 . We can also boast that years of experience have proven that our maintenance-free clamping units remain secure — even after 35 years!

We don’t just promise that our products meet the highest quality standards, you also get this in black and white in the form of internationally recognized certificates. Beyond the requirements outlined by DIN ISO 9001:2000 and ISO 14001, WAGO also fulfills the requirements set forth by all requisite maritime approvals: DNVGL, ABS, LRS, BV, KRS, classNK.

Timely engineering is an essential factor for success in today’s globally networked world. You must be able to adapt to your customers’ needs and demands in order to tap into new markets and keep ahead of competitors. WAGO supports you in these efforts with an end-to-end tool chain.

smart DESIGNER accompanies you through all phases of control cabinet engineering — with bidirectional interfaces to CAE systems, smart PRINTER and, of course, to WAGO’s e!Shop. As a result, the management of master data and parts lists can be done at one single point.

Continuous support

• e! COCKPIT for integrated engineering in automation

• smart DESIGNER for the life cycle of a control cabinet

• Seamless integration into CAE systems

e!COCKPIT invites you to discover: Your entire project in view, from graphic network design up to the parameterization and diagnostics of the WAGO-I/O-SYSTEM 750, standard-compliant programming in CODESYS 3.5, modern visualization in HTML5.

Volume 1, Rail-Mounted Terminal Block Systems

Volume 2, PCB Terminal Blocks and Connectors

Volume 3, AUTOMATION

Volume 4, INTERFACE ELECTRONIC

Volume 5, WINSTA® —The Pluggable Connection System